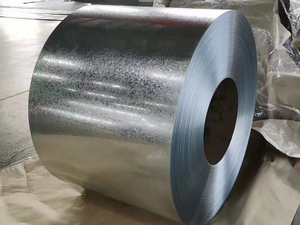

ZAM steel coil,Zinc-Aluminum-Magnesium Steel Coil is an excellent corrosion-resistant hot-dip galvanized aluminum-magnesium alloy coated steel sheet product. It is Zinc, 6% Aluminum, 3% Magnesium Alloy Coated Steel, superior corrosion-resistant and uniquely presents a self healing are the 2 main features of ZAM steel coil.. This amazing coated steel product lasts longer in the most severe environments, provides built-in cut edge rust protection, and promotes cost savings through less maintenance.Due to the effects of magnesium and aluminium, ZAM has excellent corrosion resistance, scratch resistance

Standard | ASTM A1046/A1046M Type 1,AS/NZS 1397 |

Steel grade | DX51D+ZAM, DX52D+ZAM, DX53D+ZAM, DX54D+ZAM, S220GD+ZAM, S250GD+ZAM, S280GD+ZAM, S320GD+ZAM, S350GD+ZAM, S550GD+ZAM |

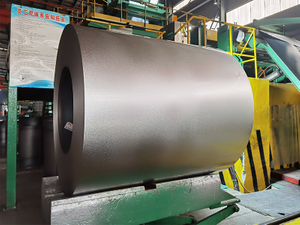

Thickness | 0.35-3.3mm |

Width | 30-1550mm |

Coil ID | 508/610MM |

Coil Weight | 3-8 tons |

Coating | ZM30-600g/m2 |

Packing | Export standard packing |

Advantages and features of Zinc-Aluminum-Magnesium Steel

ZAM steel coil is an excellent corrosion-resistant hot-dip Zinc-Aluminum-Magnesium alloy coated steel sheet product.

The product lasts longer in harsh environments, offers built-in trim edge rust protection, and saves money by reducing maintenance.

ZAM is a self-healing, eco-friendly alternative to traditional metal coatings. In addition to the key features mentioned, ZAM:

Excellent alkali resistance - even in direct contact with concrete and mortar

Great alternative to more expensive stainless steel and aluminum

Your post dip batch coated product will be ideal for conversion to cost saving ZAM coated sheet.

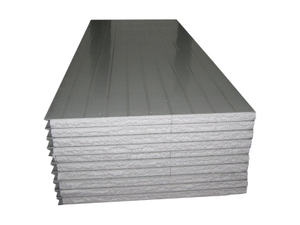

ZAM Steel coil Applications

Suitable applications for ZAM include: construction (architectural building panels, perforated panels, metal facades, roofing), automotive, agricultural applications (chicken grow outhouses, swine containment, hoop buildings, grain bins, silos, etc.), greenhouse structures, industrial HVAC, cooling towers, solar racking, school bus decking, swimming pool, signposts, guardrail facades, coastal environments, cable trays, switch boxes, steel decking and framing, sound/wind/snow barriers and many other applications.

The finished product always has a brighter and shiner surface finish than the hot-dipped version. The sheet’s surface weldability is especially better for spot and seam welds.