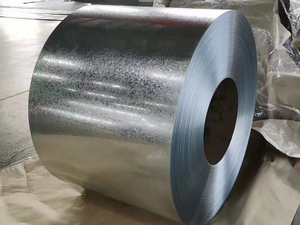

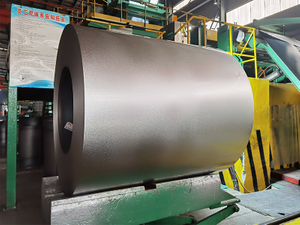

Zinc Aluminum Magnesium coil is a type of coated steel coil that consists of a combination of zinc, aluminum, and magnesium. This coating provides enhanced corrosion resistance and durability compared to traditional steel coils. Zn-Al-Mg steel coil is commonly used in applications where superior protection against harsh environmental conditions is required, such as in the construction of roofing, cladding, and automotive parts. The addition of magnesium to the coating further improves its resistance to corrosion, making it a popular choice for outdoor and high-stress environments. With its superior performance and longevity, Zn-Al-Mg steel coil is a reliable option for various industrial and commercial applications.

Standard | ASTM A1046/A1046M Type 1,AS/NZS 1397 |

Steel grade | DX51D+ZAM, DX52D+ZAM, DX53D+ZAM, DX54D+ZAM, S220GD+ZAM, S250GD+ZAM, S280GD+ZAM, S320GD+ZAM, S350GD+ZAM, S550GD+ZAM |

Thickness | 0.35-3.3mm |

Width | 30-1550mm |

Coil ID | 508/610MM |

Coil Weight | 3-8 tons |

Coating | ZM30-600g/m2 |

Packing | Export standard packing |

In addition to the key features mentioned, ZAM offers excellent alkali resistance, making it a great alternative to more expensive stainless steel and aluminum. Your post dip batch coated product will be ideal for conversion to cost-saving ZAM coated sheet. ZAM Steel coil applications are diverse, including construction, automotive, agricultural, greenhouse structures, industrial HVAC, and more. The finished product always has a brighter and shinier surface finish than the hot-dipped version, with improved surface weldability for spot and seam welds. ZAM is a versatile material that finds its place in various industries due to its durability and cost-effectiveness.

ZAM Steel coil Applications

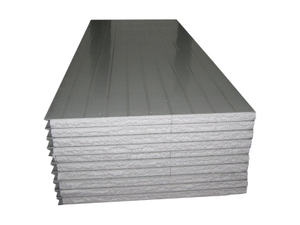

Suitable applications for ZAM include: construction (architectural building panels, perforated panels, metal facades, roofing), automotive, agricultural applications (chicken grow outhouses, swine containment, hoop buildings, grain bins, silos, etc.), greenhouse structures, industrial HVAC, cooling towers, solar racking, school bus decking, swimming pool, signposts, guardrail facades, coastal environments, cable trays, switch boxes, steel decking and framing, sound/wind/snow barriers and many other applications.

The finished product always has a brighter and shiner surface finish than the hot-dipped version. The sheet’s surface weldability is especially better for spot and seam welds.

FAQ:

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge but the delivery charges will be covered by our customers.

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp

will be online in 24 hours.Please send us your requirement , we will work out a best price soon.