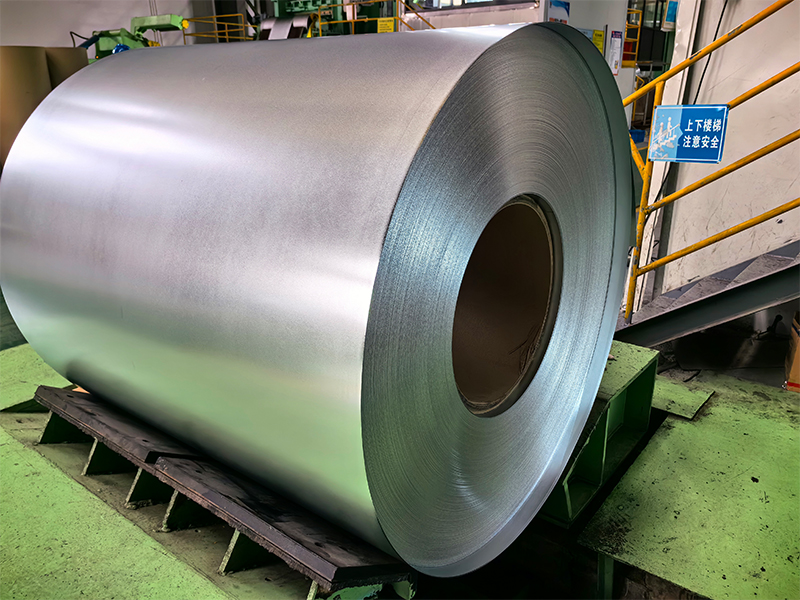

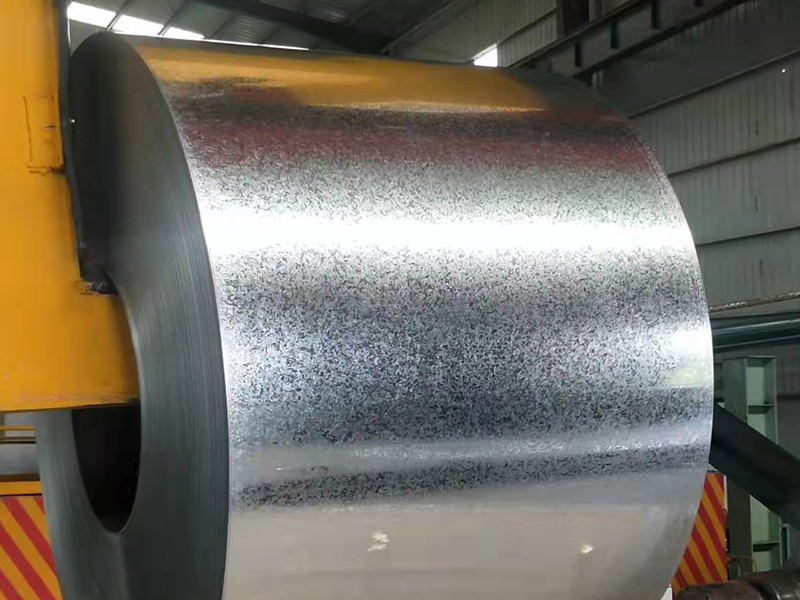

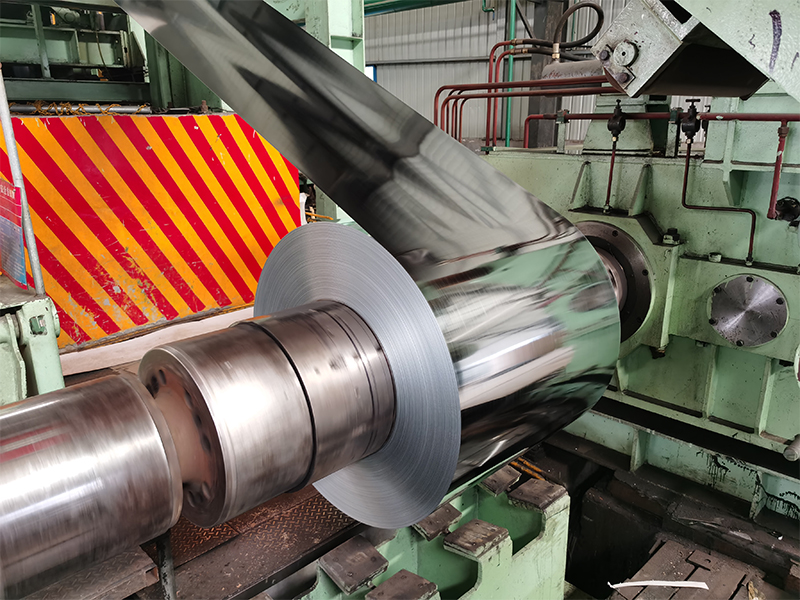

GI Steel Coil stands for Galvanized Iron Steel Coil. It is a type of steel coil that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves applying a protective zinc coating to the steel coil through a hot-dip or electroplating process. GI Steel Coils are commonly used in various industries for roofing, construction, automotive, and other applications where corrosion resistance is required. They are known for their durability, strength, and longevity, making them a popular choice for a wide range of projects.

Galvanized iron is a versatile material widely used in the manufacturing industry due to its excellent corrosion resistance properties. It is commonly employed in the production of electrical enclosures, junction boxes, and conduits to safeguard wiring and electrical components from moisture and corrosion. Additionally, galvanized iron rolls find extensive applications in various industrial settings, including the fabrication of manufacturing equipment, storage tanks, and pipelines. The durability and longevity provided by galvanized iron make it a preferred choice for applications where corrosion resistance is crucial for sustained performance. Manufacturers often provide samples of galvanized iron products, with customers only required to cover the delivery charges. This transparent approach ensures that customers can assess the quality and suitability of the products before making a purchase decision.

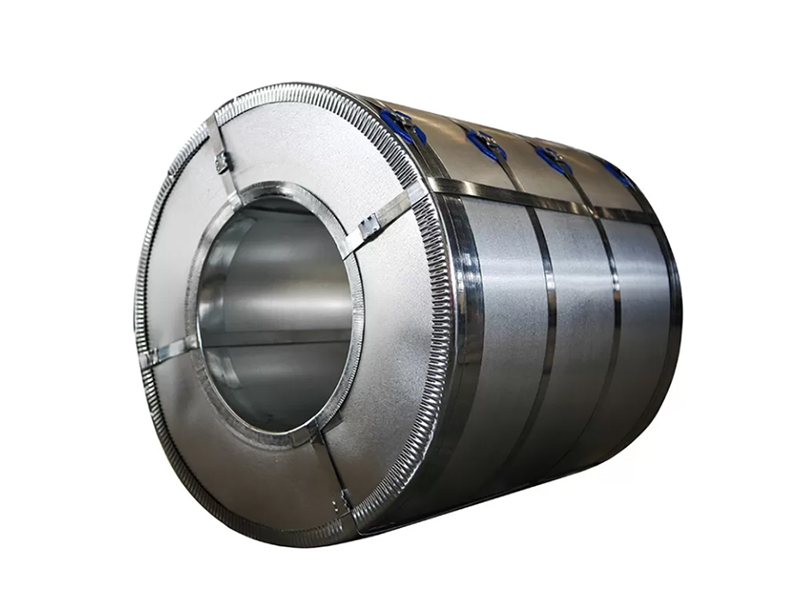

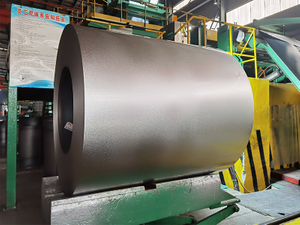

Product name | Zinc Coated Steel Coil |

Standard | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D |

Thickness | 0.105-4mm |

Width | 600mm-1250mm |

Zinc coating | 20gsm-275gsm |

Coil ID | 508/610MM |

Coil Weight | 3-8 tons |

HRB | Soft Hard(<60) Medium Hard(60-85) Full Hard(85-95) |

Spangle | Regular Spangle,Minimal Spangle, Zero Spangle,Big Spangle |

Package | standard export package |

Galvanized iron rolls have a wide range of applications across various industries due to their corrosion-resistant properties. Some common applications of galvanized iron rolls include:

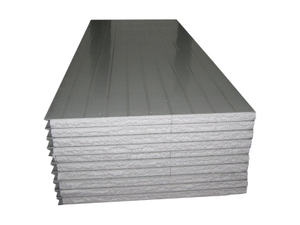

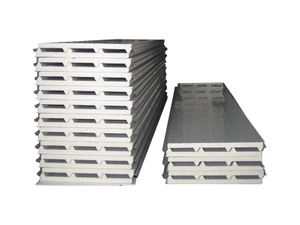

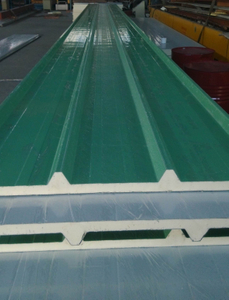

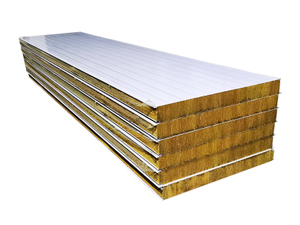

1. Roofing: Galvanized iron rolls are commonly used for roofing materials in residential, commercial, and industrial buildings due to their durability and weather resistance.

2. Construction: They are used in construction projects for making structural components, such as beams, columns, studs, and trusses, as well as for cladding and siding.

3. Automotive industry: Galvanized iron rolls are used in the manufacturing of automotive parts and components, such as body panels, chassis, and exhaust systems, to protect them from rust and corrosion.

4. HVAC systems: They are used in heating, ventilation, and air conditioning systems for ductwork, vents, and other components that are exposed to moisture and harsh environmental conditions.

5. Agricultural equipment: Galvanized iron rolls are used in the manufacturing of agricultural equipment, such as grain bins, silos, fencing, and livestock enclosures, to withstand outdoor exposure.

6. Electrical enclosures: They are used for making electrical enclosures, junction boxes, and conduits to protect wiring and electrical components from moisture and corrosion.

7. Industrial applications: Galvanized iron rolls are used in various industrial applications, such as manufacturing equipment, storage tanks, and pipelines, where corrosion resistance is essential for long-term performance.